FUTUREBUILD® LVL TCC Floors

Futurebuild® LVL Timber Concrete Composite (TCC) Floors represent a move to optimise the advantages of both Laminated Veneer Lumber (LVL) beams and a concrete screed/slab, combined using defined and tested connection methods to provide composite action.

Although the technology was only introduced to New Zealand in 2012, concrete slabs/screeds have been added to timber floors for decades in Europe - where the natural weight of concrete has been used to provide acoustic benefits. A natural progression was to provide a structural connection between the slab/screed and the timber joists, allowing for an optimised structural solution with inherent acoustic and fire benefits.

Features & Benefits

- Concrete slab/screed for enhanced acoustic attenuation*

- LVL for strength, stiffness and inherent fire resistance*

- computeIT® design software for performance optimisation

- Established, tested and proven performance

- Lightweight, enabling use of conventional timber framing support*

- Easy to install

- Cost effective*

- LVL products offer low variability and high reliability

- Futurebuild® LVL used in TCC Floors is manufactured from sustainably-grown New Zealand radiata pine

- Available Forest Stewardship Council® (FSC®) certified (FSC® C007103) upon request

* Subject to design consideration.

Contact Futurebuild® LVL for further information.

For more detailed information, please refer to our TCC Floors Information Guide.

Software

Photo Gallery

Brochure

Futurebuild LVL Timber Concrete Floors (TCC) Guide

Timber Concrete Composite (TCC) floors represent a move to optimise the advantages of both Laminated Veneer Lumber (LVL) beams and a concrete screed/slab, combined using defined connection methods to provide composite action.

Futurebuild LVL Specific Engineering Design Guide

Properties and structural characteristics for the Futurebuild LVL range for use by specifiers and engineers for specific design LVL projects.

Information Bulletin

Futurebuild LVL computeIT Software for Engineers Flyer

computeIT® is designed to aid in the specification of heavy Laminated Veneer Lumber (LVL) structural

members and non-residential structural systems. Learn more in this flyer on the computeIT software suite.

Cad

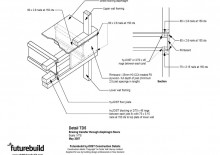

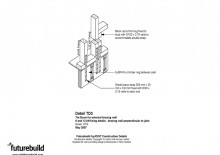

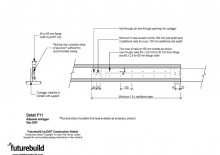

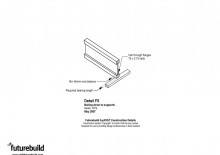

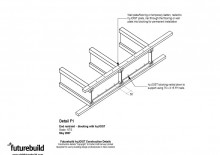

HYJ025 (TD3)

Tie-down for external bracing wall- 6 and 12 kN fixing details - bracing wall perpendicular to joist (Detail TD3)

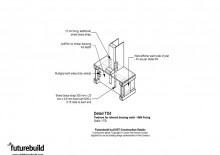

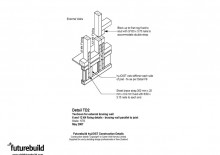

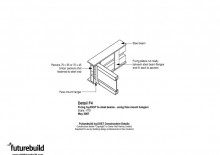

HYJ024 (TD2)

Tie-down for external bracing wall -6 and 12 kN fixing details - bracing wall parallel to joist (Detail TD2)

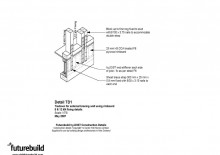

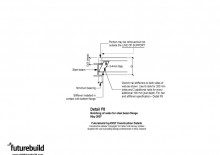

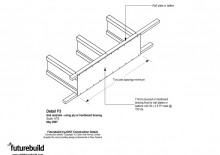

HYJ023 (TD1)

Tie-down for external bracing wall using rimboard using 6 12kN fixing detail (Detail TD1)

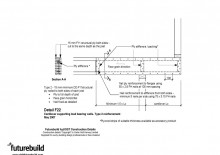

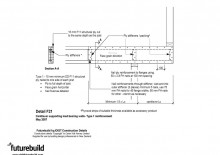

HYJ022 (F22)

Cantilever supporting load-bearing walls- Type 2 reinforcement (Detail F22)

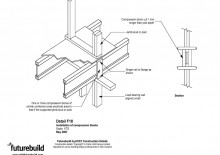

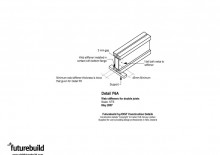

HYJ021 (F21)

Cantilever supporting load-bearing walls- Type 1 reinforcement (Detail F21)

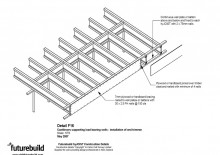

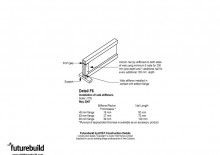

HYJ018 (F16)

Cantilevers supporting load-bearing walls - installation of end trimmer (Detail F16)

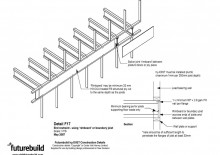

HYJ015 (F13)

hyJOIST cantilever for internal or weather-proofed balcony applications (Detail 13)

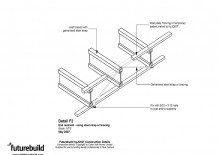

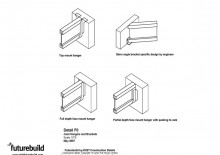

HYJ005 (F4)

Fixing hyJOIST to steel beams - using face mount hangers (Detail F4)

Building Product Information

Futurebuild LVL computeIT Software Solutions

Building Product Information Sheet and Product Technical Statement for Futurebuild LVL Products specified through the computeIT software solutions.