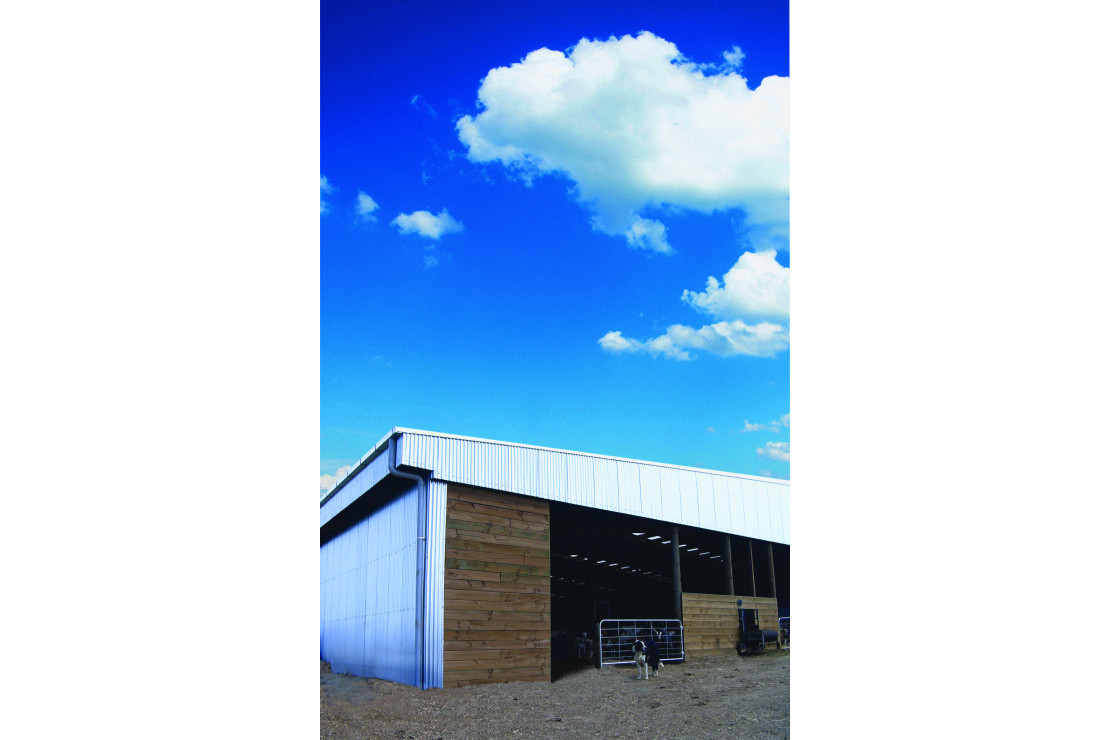

Ragtime Dairy Goats Farm

Ragtime Farm, is owned by Bill and Julia Cook and their two children. Their main business is the supply of top quality goat’s milk to Kapiti Fine Foods, producer of world class cheeses, ice creams and other goat’s milk products. The goats are milked twice daily, fed six times daily and Bill Cook puts a lot of effort into his pasture and crops which are ‘cut and carried’ to provide all natural nutrition and good animal health.

CHALLENGE

To ensure milk from the goats is of the finest quality, these Ragtime Goats also need to be treated well, nurtured and housed under five star conditions. This is where the shed comes in. Peter Hill was recommended as designer and engineer on the project that was managed by ITM Tumu, a local supplier and merchant of the Futurebuild® LVL range (laminated veneer lumber) located in Hastings.

Hill has a long time association with Futurebuild LVL, leaning heavily toward timber and Futurebuild LVL construction in all of his work. As Hill himself explains, Futurebuild LVL has its own particular intricacies and special areas that it suits most engineering applications.

The owner wanted a shed design to suit the goats’ needs and to create the desired environment. Building on a paddock, out in the rural farm setting, Hill was aware of the challenges of construction far from the services available in the city. On the other hand, the shed was not a city building but a home for goats.

SOLUTION

hySPAN® was selected as the main support for the building which covered a 1,167 m2 area. hySPAN was ideal for a farm structure as it was a large space, 42.5 metres long by 27.5 metres wide. Treated timber poles supported by a concrete foundation also provided the main support for the gabled roof. The long lengths of the hySPAN meant easy installation out in the paddock, the long spans joining the main rafters with plywood gussets. hySPAN was a good solution given the long lengths required.

The shed is spacious but just as important, the well ventilated housing for zero grazing of dairy goats means that there is no pasture contamination and the Cook’s are able to stop regular drenching. The hySPAN rafters and timber poles provided the main building structure to safely house the susceptible bleaters. The purlins run flush into the side of the main hySPAN rafters to form a clean roof line. In practical terms this means there is no space for birds to perch and do their business, creating a health hazard for the sensitive guests inside.

“hySPAN was the first choice for this job,” says Hill, “given the use and the environment, the farm scene and because it suited the structural arrangement perfectly.”

RESULT

The shed was constructed quickly and the goats are now cosy, happy and ready for milking in a clean and controlled environment; which for Kapiti and for cheese lovers all over the world is very good news.

PRODUCTS:

hySPAN®

ENGINEER:

Hill Design Engineering Ltd

CONTRACTOR/BUILDER:

Mitchell & Greatbatch Construction