Treading Water: Silverdale Northern Arena

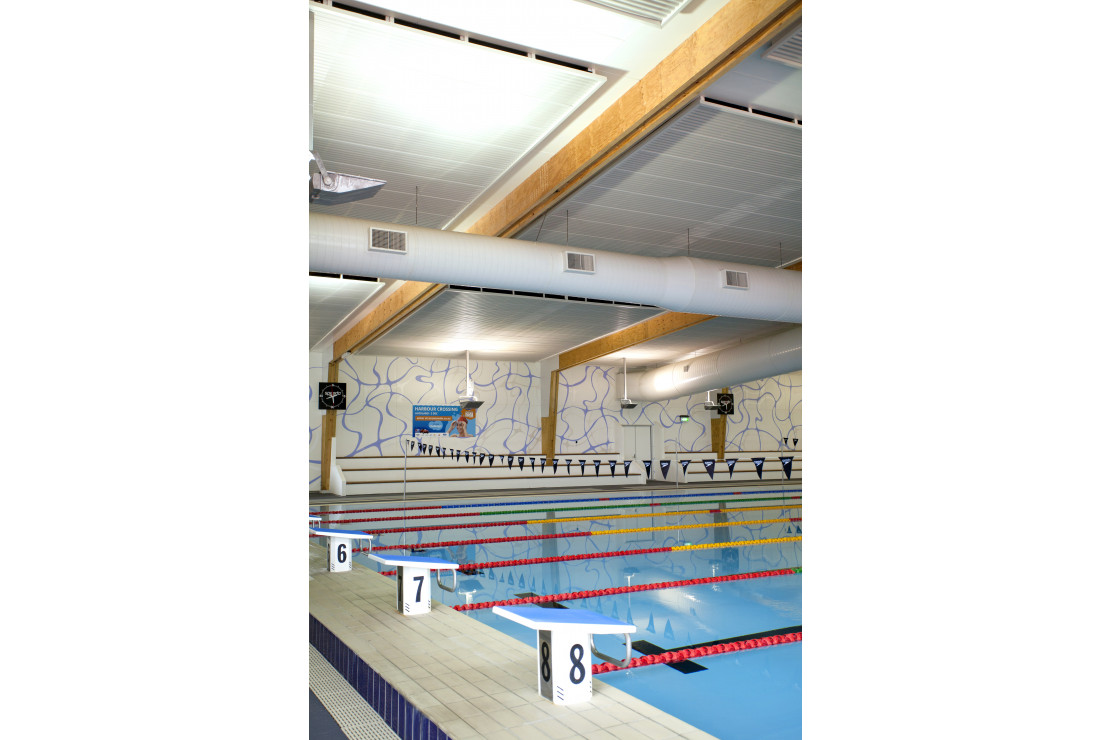

Two separate pool halls house a 25 m training pool, a 25 m teaching pool, an 11.8 m learning pool and an 11.8 m mother and baby pool. The pools have been arranged to provide for natural progression through the various lengths, depths and temperatures to suit advancing age and ability through to squads in the Training Pool.

LHTDesign of Hawkes Bay was the principal design team, controlling and co-ordinating the project. “The aim was to create a functionally practical and visually stimulating facility, whilst satisfying the projects commercial objectives,” says Bryan Greig, LHTDesign Associate and Structural Engineer.

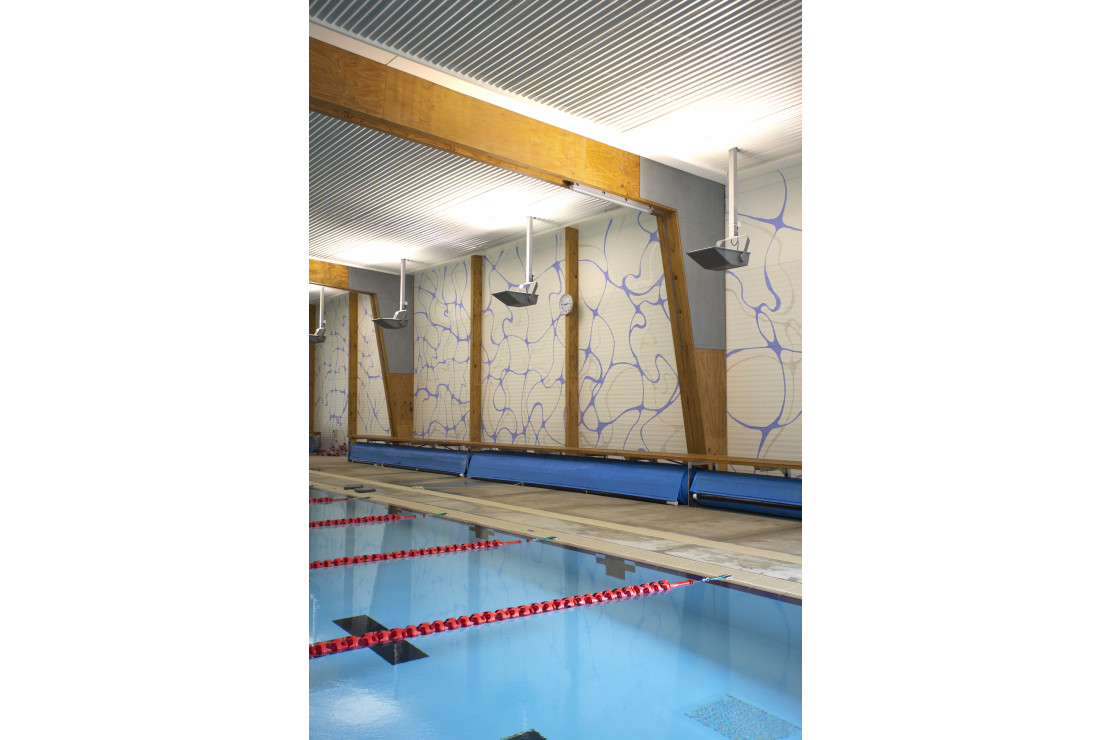

Extensive use of timber has been used in the build including the main frames spanning 34 m. “Futurebuild® LVL (laminated veneer lumber) was our preferred medium,” says Bryan. “It has a natural resistance in a corrosive environment and when running an energy efficient system you tend towards higher humidity with chlorine which is not good on steel and very costly to correct.”

At 8 m by 55 m this is a “big, tight” build and Bryan felt Futurebuild LVL would best fit the requirements based on past experience with the product. “It is strong and stable, and handles itself well in long lengths. It is also economical, particularly in comparison to GLULAM which is the alternative.”

The use of hyONE® from the Futurebuild LVL range provided the ability to get slender timber sections that still have high strength and stiffness.

The client wanted a contemporary structure with exposed materials. The end legs (hy90®) and the portal frames (hyONE) are visible and have been lightly sanded to get rid of glue marks, with a clear sealant then applied to retain a natural timber appearance.

The second stage, involving the Training Pool Hall, required extra thought on how to best assemble the double portals to the strut. “Not your usual frame configuration,” says Bryan. “We prepared a detailed methodology and in conjunction with CHH Woodproducts it worked out perfectly. Preparing as much as possible in the factory, allowed all the cuts to be done offsite, transporting the large sections to site and then erecting it very quickly, worked really efficiently.”

Bryan adds that he thinks consideration needs to be given by designers on how Futurebuild LVL is used and its properties, and advises using the team at CHH Woodproducts to that end. “That we were able to put the portals up and the sealant applied with speed reduced the exposure of Futurebuild LVL to the onsite conditions.”

The warm visual of high performing Futurebuild LVL timber was the first choice for the Northern Arena – a natural choice for a natural look.

PRODUCTS:

hyONE® & hy90®

ARCHITECT:

LHTDesign

ENGINEER:

LHTDesign

FABRICATOR:

Carters Fabrication

CONTRACTOR/BUILDER:

Livingstone Construction