FUTUREBUILD® LVL hyFRAME®

hyFRAME® is a fully engineered, prefabricated Laminated Veneer Lumber (LVL) portal frame solution, designed for use as part of your total build system. It is the ideal framing solution for both rural and light commercial buildings, including a wide range of sheds.

hyFRAME has been developed to provide a single design solution for the most common environmental conditions in New Zealand. The single design has a number of advantages to provide; efficiencies through design, fabrication and quantities of scale. As a builder, installer, or shed provider hyFRAME enables you, together with your preferred merchant, to supply a fully integrated and cost-effective shed offer to your customer. All framing components, as well as any framing technical information, are supplied in the hyFRAME kitset. The hyFRAME kitset solution allows you to select your own preferred walls and flooring to easily create a tailored building solution.Common Uses of hyFRAME Buildings:

- Warehouses

- Small scale factories

- Animal housing

- Transport depots

- Aircraft hangers

- Sports halls

- Community buildings

- Fertiliser and compost storage

Features & Benefits

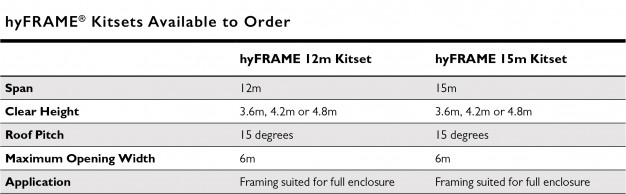

- Ease of design - available in pre-designed 12m or 15m wide spans with, 3.6m, 4.2m or 4.8m clear heights and 6m bay increments

- Smart and fast – the kitset-like construction process ensures accuracy of assembly and can reduce build time and minimise construction errors

- Corrosion resistance - LVL is naturally resistant to most corrosive chemicals, largely unaffected by most acids and alkaline environments (stainless steel fasteners available on request)

- Aesthetics – the natural warmth and look and feel of timber

- Strength - LVL framing has high structural reliability and low variability with a superior strength to weight ratio compared to hot rolled steel

- Keep it green - hyFRAME® LVL is manufactured from sustainably-grown New Zealand radiata pine

- Available Forest Stewardship Council® (FSC®) certified (FSC® C007103) upon request

- Compliance – Futurebuild LVL is manufactured to AS/NZS 4357 and is JAS-ANZ accredited by the Engineered Wood Products Association of Australasia (EWPAA)

Included with all hyFRAME® kitsets:

- Structural drawings and calculations, including PS1

- All LVL components including

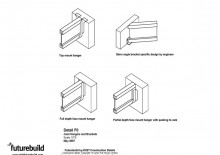

- Prefabricated portal frame components

- Purlins, blocking and lateral restraints

- Girts and girt involving

- End wall framing

- Bracing, footing brackets, purlin and girt brackets

- All fixings and fasteners required for on-site erection

- Technical assembly support

- Delivery to merchant

- Waterproof construction plans

Note: Contact the Futurebuild LVL Team to confirm suitability of hyFRAME for site specific conditions.

WHAT ELSE WILL YOU NEED?

Outside of the hyFRAME Kitset there are some other items to consider when putting together your total customer solution:

- Concrete slab or alternative floors

- Mid floors or enclosed bays if required

- Resource consent requirements

- Architectural design and drawings

- Cladding

- Roofing

- Flashings

- Doors

These items above are not supplied by Futurebuild LVL.

Finishes are best selected to suit each projects applications.

Futurebuild can provide some technical insights in relation to finishing but recommend sites are finished with product best for each projects commercial application.

For more technical information or to discuss using hyFRAME, get started today by contacting the Futurebuild Technical Team on 0800 585 244 or email info@futurebuild.co.nz.

Software

Photo Gallery

Information Bulletin

Brochure

Futurebuild LVL hyFRAME - The LVL Kitset Portal Frame Solution Brochure

hyFRAME® is a fully engineered, prefabricated Laminated Veneer Lumber (LVL) portal frame, designed for use as part of your total build system. It is the ideal framing solution for both rural and light commercial buildings, including a wide range of sheds.

Technical Note

Futurebuild LVL and Treatment For Use in Buildings

Technical Note relating to treatment for use in buildings

Futurebuild LVL Trouble with Substitutes

Think hard and check before substituting one building product for another. Get it wrong and you could be creating quality issues and have trouble getting a Code Compliance Certificate.

Cad

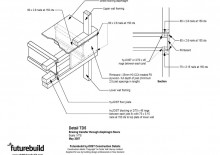

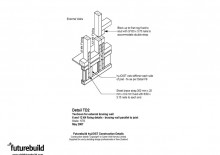

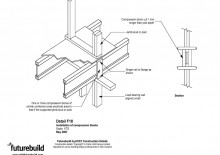

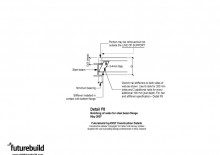

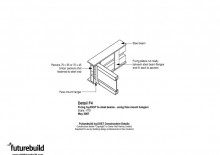

HYJ025 (TD3)

Tie-down for external bracing wall- 6 and 12 kN fixing details - bracing wall perpendicular to joist (Detail TD3)

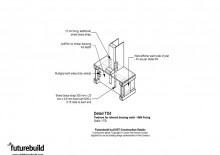

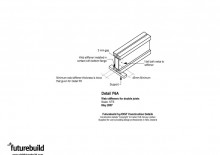

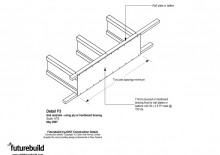

HYJ024 (TD2)

Tie-down for external bracing wall -6 and 12 kN fixing details - bracing wall parallel to joist (Detail TD2)

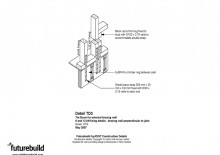

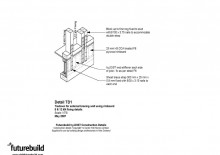

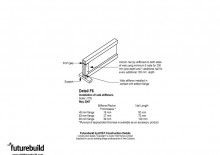

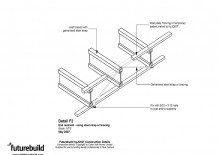

HYJ023 (TD1)

Tie-down for external bracing wall using rimboard using 6 12kN fixing detail (Detail TD1)

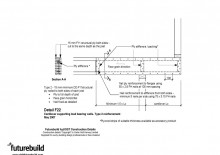

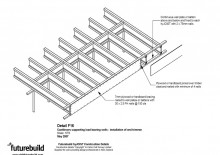

HYJ022 (F22)

Cantilever supporting load-bearing walls- Type 2 reinforcement (Detail F22)

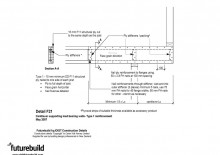

HYJ021 (F21)

Cantilever supporting load-bearing walls- Type 1 reinforcement (Detail F21)

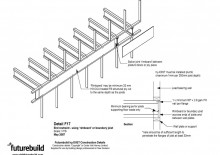

HYJ018 (F16)

Cantilevers supporting load-bearing walls - installation of end trimmer (Detail F16)

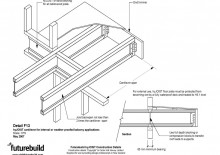

HYJ015 (F13)

hyJOIST cantilever for internal or weather-proofed balcony applications (Detail 13)

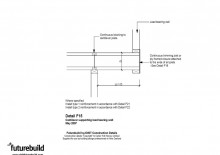

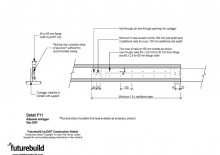

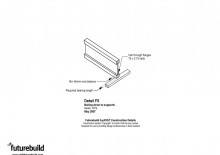

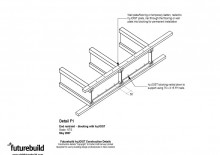

HYJ005 (F4)

Fixing hyJOIST to steel beams - using face mount hangers (Detail F4)